Crawl Space Insulation: Stop Cold Floors NOW!

Proper crawl space insulation creates a conditioned space that eliminates cold floors and reduces energy costs by 15-30%.

Tired of walking on ice-cold floors in your own home? The solution is hiding right beneath your feet.

Picture this: It’s a chilly winter morning in Anchorage. You swing your legs out of bed, and the moment your bare feet touch the floor, you wince. Despite your thermostat reading 72°F, your floors feel like they belong in a refrigerator. You’ve tried thick socks, area rugs, even slippers—but nothing seems to work.

The culprit? Your crawl space.

That dark, often-forgotten space beneath your home is secretly sabotaging your comfort and draining your wallet. According to the U.S. Department of Energy, proper crawl space insulation can reduce your heating and cooling costs by up to 20%. That’s not just comfort—that’s real money back in your pocket.

Here’s the good news: modern crawl space insulation technology has revolutionized how we solve cold floor problems. By sealing and insulating your crawl space correctly, you can eliminate those frigid floors, slash your energy bills by 15-30%, and even qualify for federal tax credits of up to $1,200 and Alaska rebates totaling $2,700-$4,500.

In this comprehensive guide, we’ll show you exactly how crawl space insulation works, which materials deliver the best results, and how to stop cold floors for good. Whether you’re an Anchorage homeowner battling Alaska’s extreme cold or simply want to understand your options, you’re in the right place.

Key Statistics at a Glance

Why Are My Floors So Cold? The Crawl Space Connection

The Hidden Problem Beneath Your Feet

Your crawl space is the unsung villain of home comfort problems. This low-clearance area between your floor and the ground might be out of sight, but its effects are impossible to ignore—especially when you’re walking on freezing floors.

Here’s a startling fact from building science research: up to 50% of the air in your living space originates from your crawl space. This phenomenon, called the “stack effect,” occurs because warm air naturally rises through your home, pulling replacement air up from below. If your crawl space is cold, damp, or contaminated, that’s exactly what you’re breathing.

The Environmental Protection Agency notes that indoor air can be 5 to 100 times more polluted than outdoor air—and crawl spaces are often the source. Musty odors, excess humidity, and that persistent floor chill? They’re all connected to what’s happening beneath your feet.

Common Causes of Cold Floors

Cold floors don’t just happen by accident. Several factors contribute to this uncomfortable problem:

Inadequate or Missing Insulation

Many older homes were built with minimal or no crawl space insulation. Even homes with insulation often have outdated materials that have degraded over time.

Failed Fiberglass Batt Insulation

Traditional fiberglass insulation—the pink or yellow stuff you’ve probably seen—is notorious for failing in crawl spaces. It absorbs moisture, becomes heavy, sags from between floor joists, and eventually falls to the ground. When this happens, your floor has zero insulation protection.

Air Leaks and Drafts

Unsealed crawl spaces allow cold outside air to flow directly beneath your floors. Foundation vents, intended to provide ventilation, often become highways for frigid winter air.

Thermal Bridging

Floor joists act as thermal bridges, conducting cold directly from your crawl space into your floor. Even with insulation between joists, these wooden pathways can make floors feel cold to the touch.

Vented Crawl Spaces

For decades, building codes required foundation vents to “dry out” crawl spaces. Modern building science has proven this approach often makes problems worse, especially in humid climates where outdoor air brings moisture in rather than carrying it out. Warning Signs Image

Six warning signs that indicate your crawl space needs insulation attention.

What is Crawl Space Insulation and How Does It Work?

Definition and Purpose

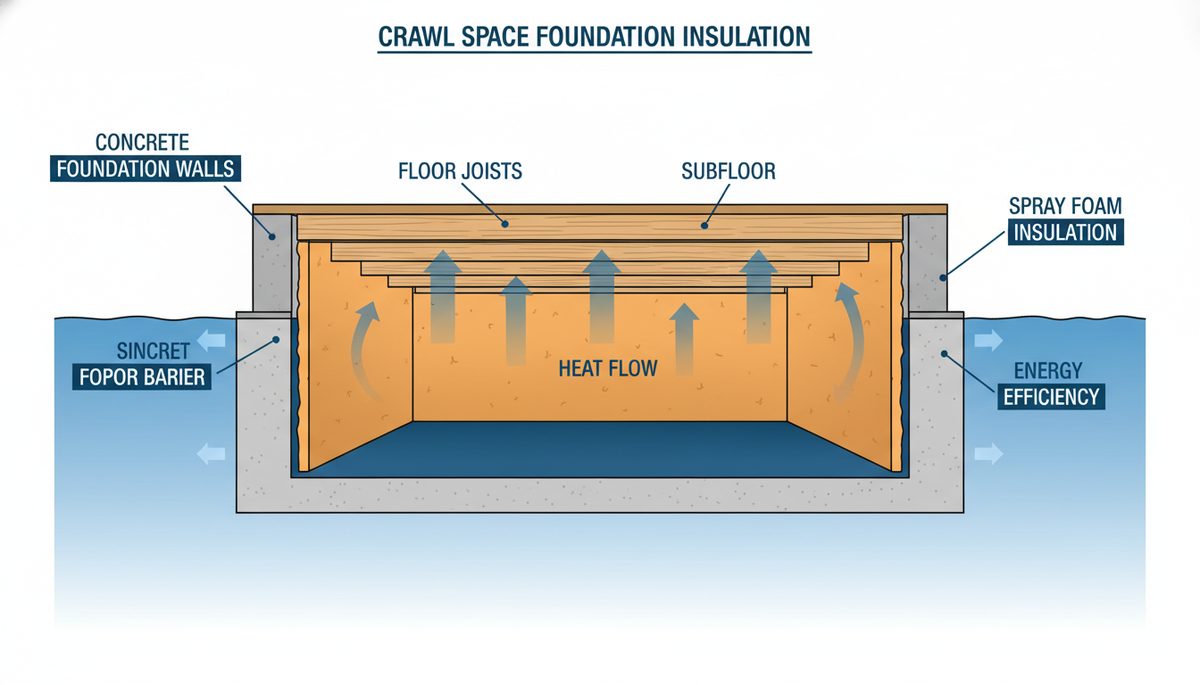

Crawl space insulation is a thermal barrier installed in the crawl space area beneath your home to prevent heat transfer between the ground, outdoor air, and your living space above. Think of it as a cozy blanket wrapping the underside of your home.

There are two primary approaches to crawl space insulation:

- Ceiling Insulation (Floor Joists): Installing insulation between the floor joists on the ceiling of your crawl space

- Wall Insulation (Perimeter): Insulating the foundation walls around your crawl space

Here’s what Building Science Corporation research conclusively demonstrates: wall insulation dramatically outperforms ceiling insulation in terms of energy efficiency, moisture control, and long-term durability. This finding has revolutionized how professionals approach crawl space insulation.

How Crawl Space Insulation Stops Cold Floors

When done correctly, crawl space insulation transforms your crawl space into a conditioned space—part of your home’s thermal envelope rather than a cold, exterior area. Here’s how it eliminates cold floors:

Creates a Thermal Barrier: Wall insulation prevents cold from entering through the foundation, keeping the entire crawl space closer to your home’s temperature.

Eliminates Air Infiltration: Spray foam insulation seals gaps and cracks where cold air would otherwise infiltrate, stopping drafts at the source.

Prevents Thermal Bridging: By insulating walls rather than between joists, you eliminate the thermal bridges that conduct cold into your floor system.

Protects Pipes and Ducts: A conditioned crawl space keeps plumbing and HVAC ductwork within a temperature-controlled environment, preventing frozen pipes and energy waste.

The result? Floors that feel comfortable year-round, not like walking on ice.

Best Insulation Materials for Crawl Spaces: A Complete Comparison

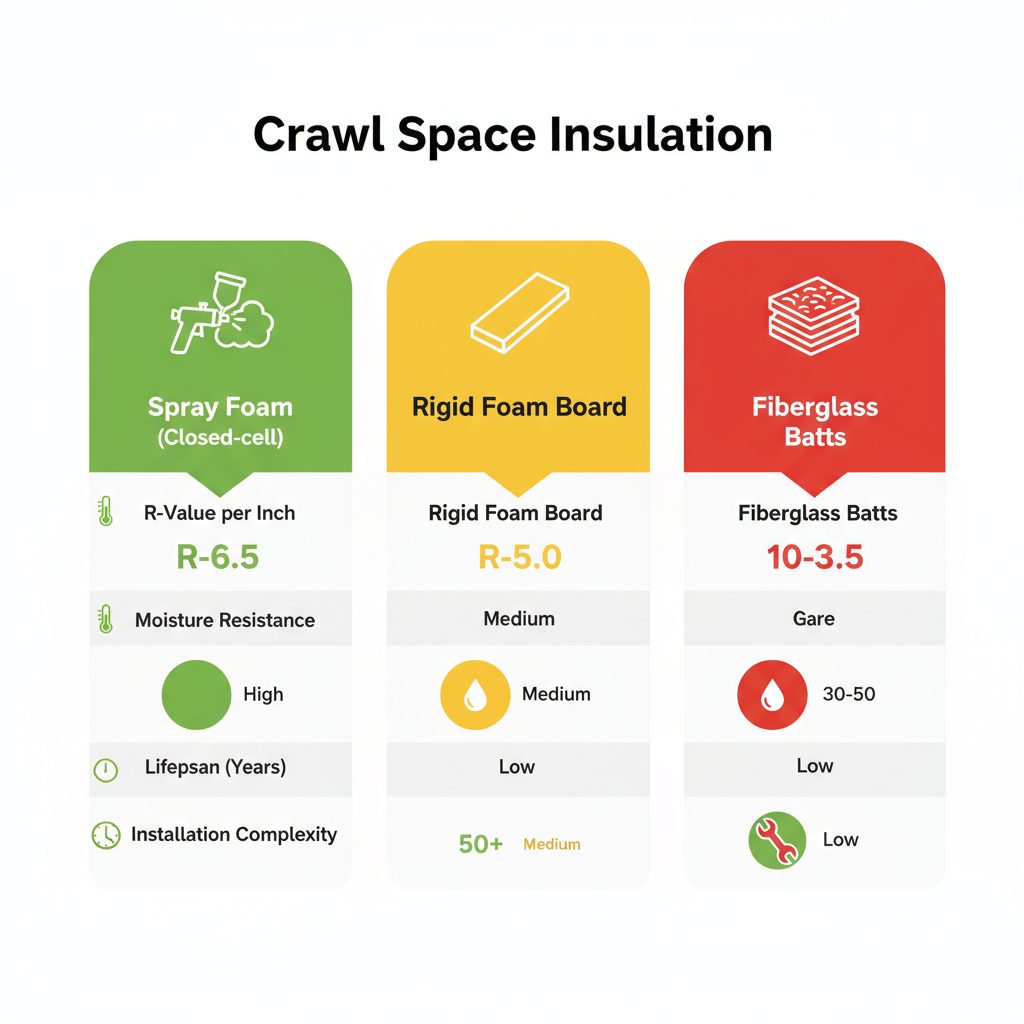

Not all insulation is created equal—especially for crawl spaces. The unique environment beneath your home demands materials that resist moisture, maintain their position, and deliver consistent thermal performance for decades. Materials Comparison Image

Comparison of crawl space insulation materials showing key performance metrics.

Closed-Cell Spray Foam (Best Choice)

Closed-cell spray polyurethane foam is the gold standard for crawl space insulation, and for good reason. This rigid, high-density material provides:

- Superior R-Value: R-6 to R-7 per inch—the highest thermal resistance of any common insulation material. Just 2-3 inches provides R-12 to R-21.

- Built-In Moisture Resistance: Closed-cell foam is impermeable to water vapor, functioning as both insulation and vapor barrier in one application.

- Air Sealing Properties: Spray foam expands to fill gaps, cracks, and irregular surfaces, creating an airtight seal that stops drafts completely.

- Structural Enhancement: When applied to walls, closed-cell foam adds rigidity and strength to the structure.

- Exceptional Longevity: Properly installed spray foam can last the lifetime of your home—20+ years with no degradation.

Cost: $2-$5 per square foot installed

Consideration: Requires professional installation with specialized equipment. This is not a DIY material.

Rigid Foam Board (Good Alternative)

Rigid foam insulation boards—including XPS (extruded polystyrene), EPS (expanded polystyrene), and polyisocyanurate—offer an excellent alternative for crawl space walls:

- Solid R-Value: R-4 to R-6.5 per inch depending on material type

- Moisture Resistance: Does not absorb water and resists mold growth

- DIY-Friendly: Rigid panels can be cut with standard tools and installed with construction adhesive and mechanical fasteners

- Long Lifespan: 20-40 years when protected from UV exposure

Cost: $1-$4 per square foot installed

Best Application: Large, flat wall sections where boards can be easily fitted. Often combined with spray foam at rim joists and irregular areas for a hybrid approach.

Fiberglass Batts (Avoid for Crawl Spaces)

Traditional fiberglass batt insulation—while common and inexpensive—is a poor choice for crawl spaces. Here’s why building scientists and experienced contractors consistently warn against it:

- Absorbs Moisture: Fiberglass acts like a sponge, absorbing humidity and condensation. Wet fiberglass loses up to 50% of its insulating value.

- Sags and Falls: Gravity and moisture cause fiberglass batts to sag, compress, and eventually fall from between joists. This is not a question of “if” but “when.”

- Promotes Mold Growth: The paper or foil facing on fiberglass batts becomes a food source for mold when damp.

- No Air Sealing: Fiberglass provides zero resistance to air movement. Cold air flows right through it.

- Short Lifespan in Crawl Spaces: While fiberglass can last decades in dry attics, crawl space installations typically fail within 5-15 years.

Cost: $0.60-$1.10 per square foot—cheap initially, expensive when you factor in replacement.

Dr. Joseph Lstiburek of Building Science Corporation puts it simply: “Warm wood is dry wood. Warm wood is happy wood.” Fiberglass in crawl spaces creates cold surfaces that attract condensation—the opposite of what you want.

Material Comparison at a Glance

| Material | R-Value/Inch | Moisture Resistant | Air Sealing | DIY Friendly | Cost/Sq Ft | Lifespan |

|---|---|---|---|---|---|---|

| Closed-Cell Spray Foam | R-6 to R-7 | Excellent | Yes | No | $2-$5 | 20+ years |

| Rigid Foam Board | R-4 to R-6.5 | Good | No | Yes | $1-$4 | 20-40 years |

| Fiberglass Batts | R-3 to R-4 | Poor | No | Yes | $0.60-$1.10 | 5-15 years* |

*In crawl space applications; fails faster due to moisture

Should I Insulate Crawl Space Walls or Ceiling?

This is one of the most important decisions in crawl space insulation—and decades of building science research have given us a definitive answer.

Why Wall Insulation is Best Practice

The Building Science Corporation, working with the U.S. Department of Energy’s Building America Program, conducted extensive research comparing wall-insulated sealed crawl spaces to ceiling-insulated vented crawl spaces. Their conclusion was unequivocal:

“Unvented, conditioned crawl spaces with insulation on the perimeter perform better in terms of safety and health (pest control), comfort (warm floors, uniform temperatures), durability (moisture) and energy consumption than passively vented crawl spaces with sub floor insulation.”

Here’s why wall insulation wins:

- Creates Conditioned Space: Insulating walls brings your crawl space into your home’s thermal envelope. The space stays closer to indoor temperature year-round.

- Protects Plumbing and Ductwork: Pipes and HVAC equipment within a conditioned crawl space are protected from freezing and temperature extremes.

- Eliminates Thermal Bridging: Wall insulation creates a continuous thermal barrier rather than leaving floor joists exposed to cold.

- Simplifies Moisture Control: A sealed, conditioned crawl space is easier to keep dry than a vented one.

- Endorsed by Building Codes: The International Residential Code (IRC) explicitly allows and supports sealed crawl space construction.

When Ceiling Insulation Might Apply

There are limited situations where insulating between floor joists might be considered:

- Very dry climates with no moisture concerns

- Homes where wall access is impossible

- Temporary solutions before full encapsulation

However, even in these cases, ceiling insulation has a high failure rate. If you go this route, you must address air sealing separately—and expect to replace the insulation eventually.

The Modern Approach: Sealed, Conditioned Crawl Spaces

Today’s best practice combines several elements into a comprehensive system:

- Seal Foundation Vents: Close and seal all exterior vents permanently

- Install Vapor Barrier: Cover the ground with a heavy-duty (12-20 mil) polyethylene vapor barrier, extending up the walls

- Insulate Perimeter Walls: Apply spray foam or rigid foam board to foundation walls and rim joists

- Control Humidity: Add a dehumidifier or supply small amounts of conditioned air to maintain humidity below 60%

Research from Advanced Energy found this approach delivers nearly 20% energy savings compared to traditional vented crawl spaces—plus dramatically better moisture control and indoor air quality. Encapsulation vs Insulation Image

Full encapsulation with wall insulation provides superior moisture control and energy efficiency compared to insulation alone.

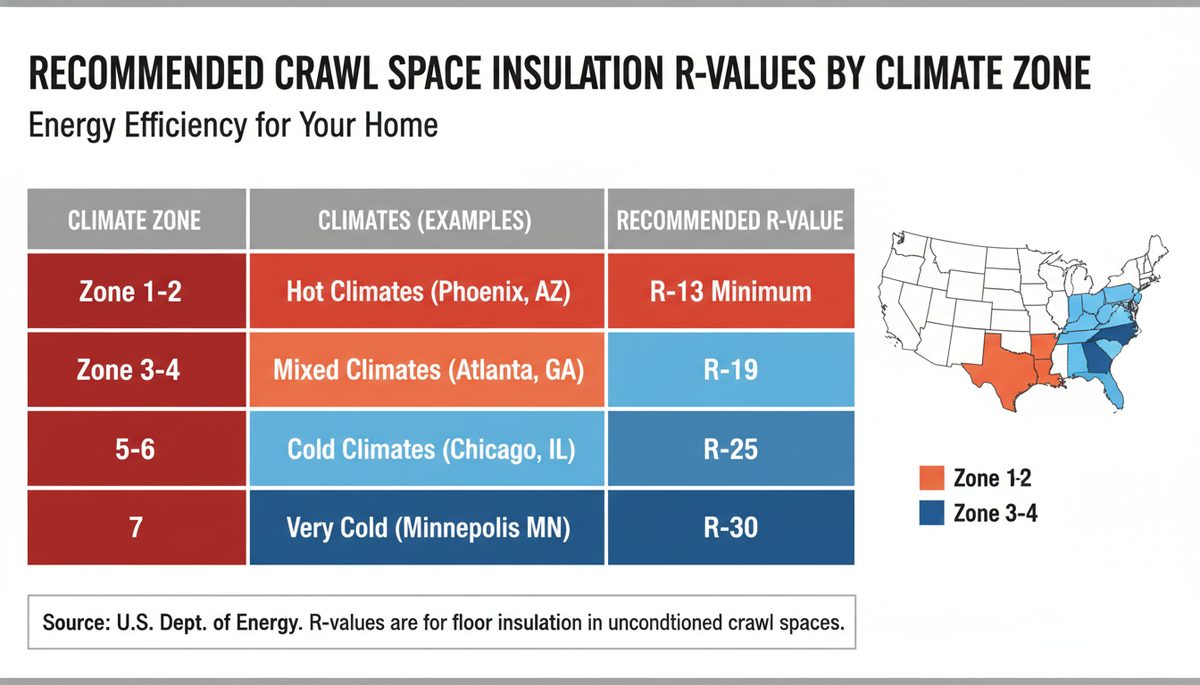

What R-Value Do I Need for Crawl Space Insulation?

R-value measures thermal resistance—the ability of insulation to resist heat flow. Higher R-values mean better insulation performance. But how much R-value does your crawl space actually need?

R-Value Basics

Every insulation material has an R-value per inch of thickness. To calculate total R-value, multiply the R-value per inch by the number of inches installed. For example:

- 2 inches of closed-cell spray foam (R-7/inch) = R-14

- 3 inches of XPS rigid foam (R-5/inch) = R-15

Building codes establish minimum R-values based on your climate zone, recognizing that colder regions need more insulation than warmer ones.

R-Value Requirements by Climate Zone

R-Value Chart Image

R-value requirements increase as you move from hot to cold climate zones.

The International Energy Conservation Code (IECC) divides North America into eight climate zones. Here’s what’s required for crawl space insulation:

| Climate Zone | Examples | Wall Insulation | Floor Insulation (if vented) |

|---|---|---|---|

| Zone 1 | Miami, Hawaii | None required | None required |

| Zone 2 | Phoenix, Houston | R-10 | R-13 |

| Zone 3 | Atlanta, Dallas | R-10 | R-13 |

| Zone 4 | Seattle, St. Louis | R-10 to R-15 | R-19 |

| Zone 5 | Chicago, Boston | R-15 | R-19 to R-30 |

| Zone 6 | Minneapolis | R-15 to R-20 | R-30 |

| Zone 7-8 | Anchorage, Fairbanks, Mat-Su Valley | R-20+ | R-38 |

Alaska Requirements

Anchorage and most of Alaska fall into Climate Zone 7, with interior and northern regions in Zone 8. For Anchorage-area crawl spaces, you need R-20+ wall insulation and R-38 floor insulation to meet code—significantly higher than warmer states. This is why proper insulation is so critical here.

Exceeding Minimum Requirements

Code requirements represent minimums—not optimums. Should you exceed them?

Yes, when:

- Energy costs are high and you want maximum savings

- Comfort is a top priority (higher R-value = more consistent temperatures)

- You’re in a border zone between climate regions

Diminishing returns: Each additional inch of insulation provides incrementally less benefit than the previous inch. Going from R-0 to R-10 might save 40% on heat loss, but R-10 to R-20 might only add 15% more savings. Beyond a certain point, the cost of additional insulation exceeds the energy savings it provides.

For most Alaska homes, R-13 to R-19 in crawl spaces provides the optimal balance of performance and cost-effectiveness.

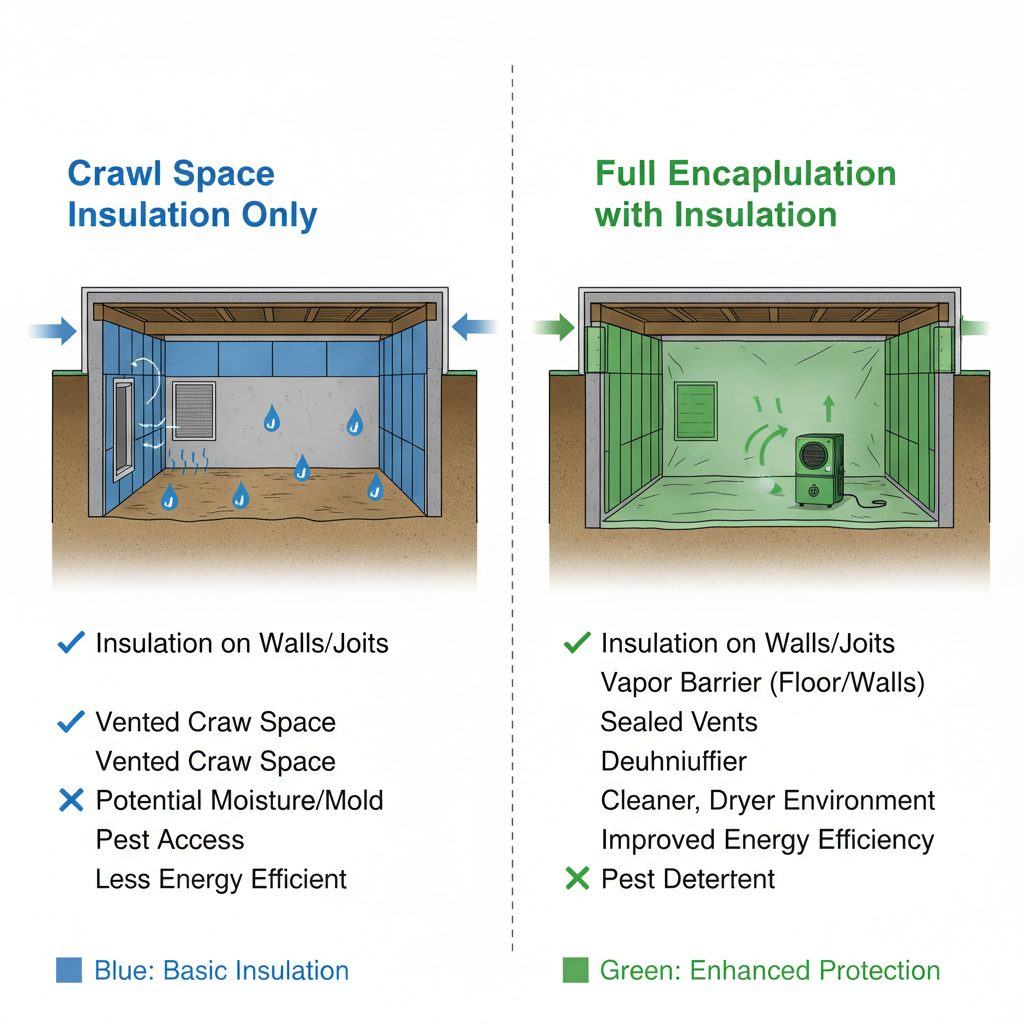

Crawl Space Encapsulation vs Insulation: What’s the Difference?

These terms often cause confusion, but understanding the distinction helps you make the right investment for your home.

Defining Each Approach

Insulation controls temperature by providing a thermal barrier. Its primary job is to slow heat transfer, keeping your home cooler in summer and warmer in winter. Insulation addresses the “cold floor” problem directly.

Encapsulation controls moisture by sealing the crawl space from ground moisture and outdoor humidity. It typically includes:

- Heavy-duty vapor barrier (12-20 mil polyethylene) covering the floor and walls

- Sealed foundation vents

- Sealed access doors

- Often a dehumidifier to maintain low humidity

Think of insulation as a winter coat (temperature control) and encapsulation as a raincoat (moisture control). Both serve important but different purposes.

Do You Need Both?

In most cases, yes—you’ll want both insulation and encapsulation working together.

Insulation alone won’t solve moisture problems. If your crawl space has humidity issues, mold growth, or standing water, adding insulation without addressing moisture will only trap problems beneath your home.

Encapsulation alone won’t stop cold floors. A vapor barrier keeps moisture out but does nothing to insulate against temperature transfer. Your floors will still feel cold.

The ideal approach combines both:

- Address any water intrusion issues (drainage, grading, gutters)

- Install comprehensive vapor barrier (encapsulation)

- Insulate perimeter walls with spray foam or rigid foam

- Add dehumidification to maintain humidity below 60%

This comprehensive approach is what building scientists mean when they recommend “sealed, conditioned crawl spaces.”

Comparison at a Glance

| Feature | Insulation Only | Encapsulation Only | Both Together |

|---|---|---|---|

| Stops cold floors | Yes | No | Yes |

| Controls moisture | No | Yes | Yes |

| Prevents mold | No | Partially | Yes |

| Energy savings | 10-15% | 5-10% | 15-30% |

| Protects structure | Partially | Yes | Yes |

| Improves air quality | Partially | Yes | Yes |

| Typical cost | $2,000-$4,000 | $1,500-$8,000 | $4,000-$12,000 |

Crawl Space Insulation Cost: Complete 2025 Pricing Guide

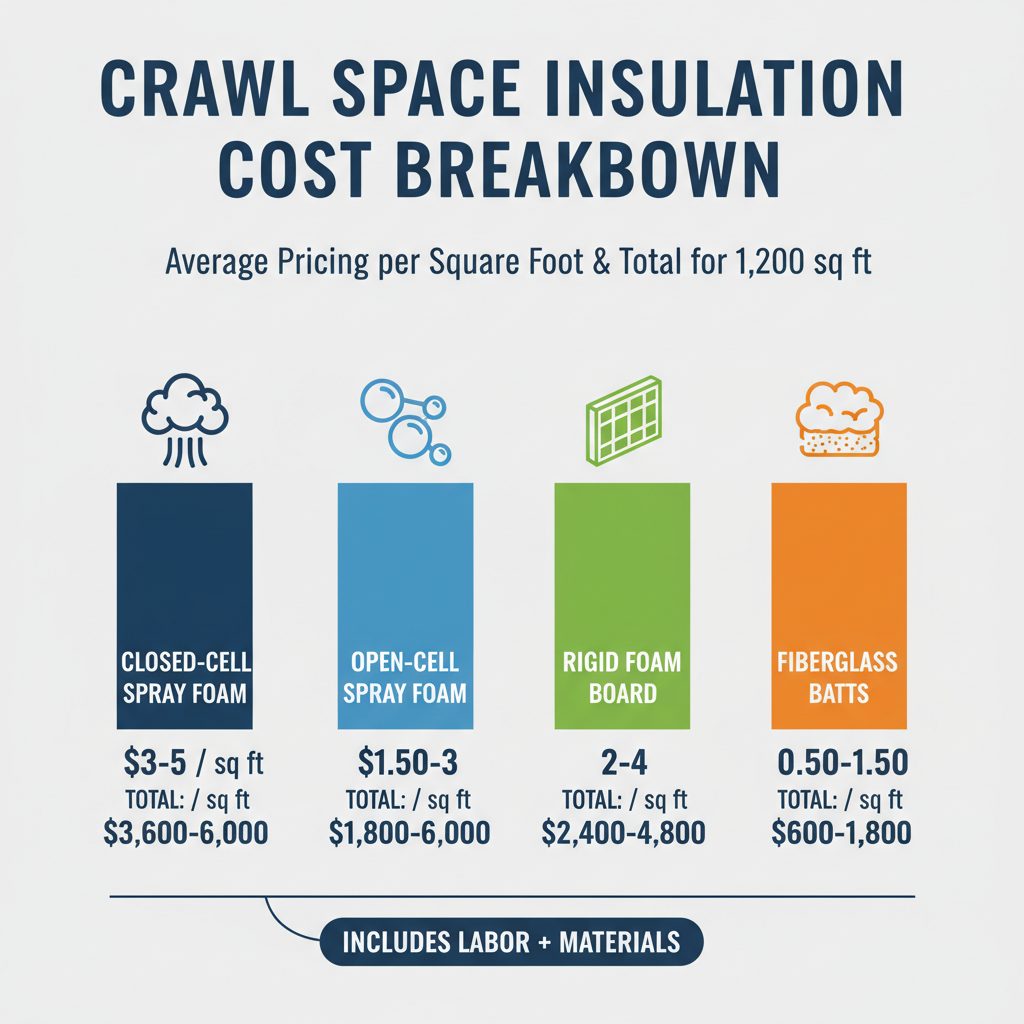

Understanding costs upfront helps you budget appropriately and evaluate contractor quotes. Here’s what to expect in 2025. Cost Breakdown Image

Crawl space insulation costs vary significantly by material type and project scope.

Average Costs and Ranges

For a typical 1,000 square foot crawl space:

- Average Total Cost: $3,550

- Low End: $2,600 (basic insulation only)

- High End: $16,900 (complete encapsulation with spray foam)

Cost per square foot typically ranges from $1.00 to $4.50, depending on:

- Material selection

- Accessibility of the space

- Current condition (existing insulation removal, moisture remediation)

- Regional labor rates

- Contractor expertise

Cost by Material Type

| Material | Cost per Sq Ft | 1,000 Sq Ft Project |

|---|---|---|

| Closed-Cell Spray Foam | $2.00-$5.00 | $2,000-$5,000 |

| Open-Cell Spray Foam | $1.00-$2.00 | $1,000-$2,000 |

| Rigid Foam Board | $1.00-$4.00 | $1,000-$4,000 |

| Fiberglass Batts | $0.60-$1.10 | $600-$1,100 |

| Vapor Barrier (20 mil) | $0.50-$1.50 | $500-$1,500 |

| Old Insulation Removal | $0.75-$2.00 | $750-$2,000 |

Labor typically adds $0.50 to $1.30 per square foot on top of materials.

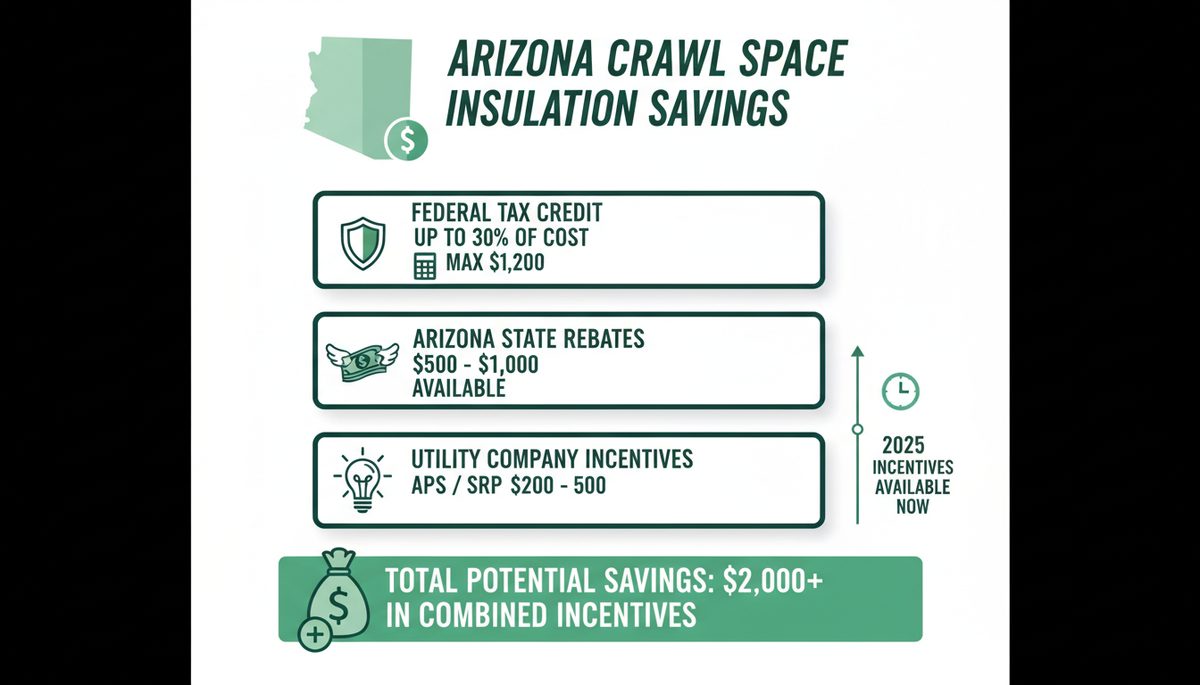

Federal Tax Credits and Alaska Rebates

This is where crawl space insulation gets exciting—2025 offers some of the best incentives in history. Alaska Rebates Image

Alaska homeowners can access $2,700-$4,500+ in combined rebates and tax credits for insulation projects.

Federal Energy Efficient Home Improvement Credit (25C)

30% of project costfor insulation materialsMaximum: $1,200 per yearAvailable through: December 31, 2032How to claim: File IRS Form 5695 with your tax return

Alaska EFFICIENCY ARIZONA Program

Through the federal DOE Home Energy Rebates program, Alaska homeowners can access:

- HOMES Rebate: Up to $4,000 based on energy savings achieved (doubles for qualified lower-income households)

- HEAR Rebate: Up to $14,000 for low and middle-income homeowners

Utility Rebates

- APS:$250 rebatefor insulation through their Home Performance Program

- SRP: Up to $600 forattic insulation, $250 for air sealing

Total Potential Savings: According to Koala Insulation, Alaska homeowners combining all available programs can save $2,700 to $4,500 on a typical insulation project.

Return on Investment

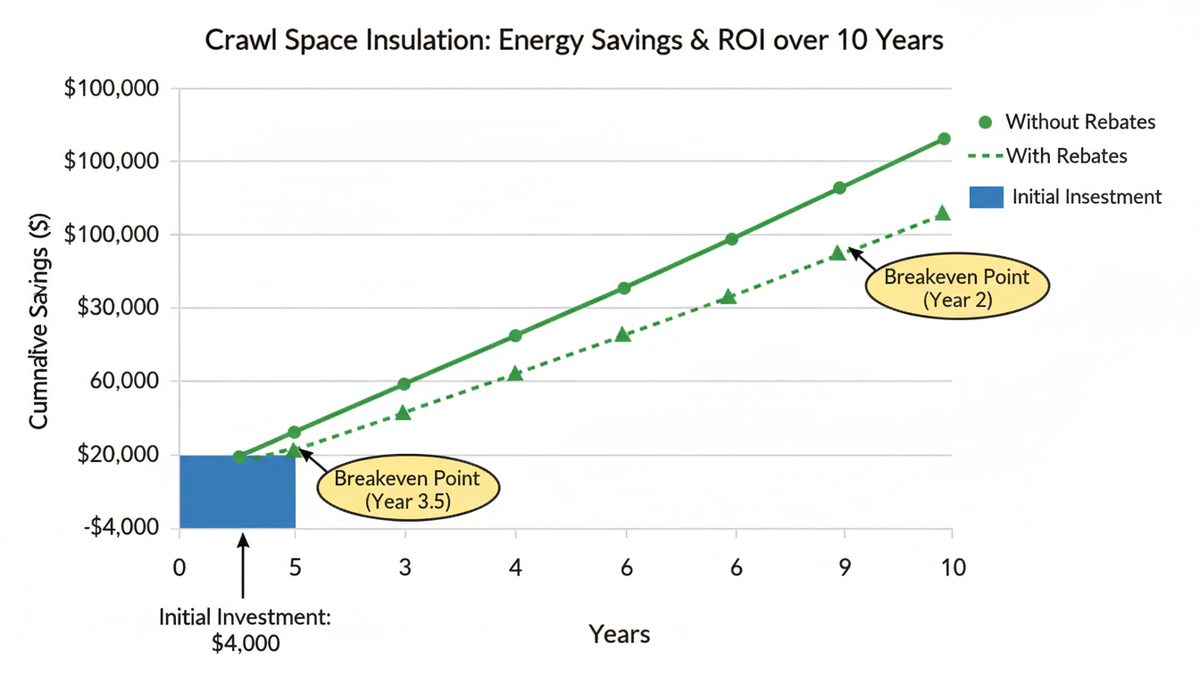

Crawl space insulation is one of the highest-ROI home improvements available:

- Energy Savings: 15-30% reduction in heating/cooling costs

- Average Annual Savings: $300-$600 for a typical Alaska home

- Payback Period: 3-7 years depending on project cost and energy savings

- Additional Value: Increased home comfort, improved air quality, protection against moisture damage Energy Savings Graph

Most homeowners recover their insulation investment in 3-7 years, then continue saving $300-$600+ annually.

Can I DIY Crawl Space Insulation or Should I Hire a Professional?

This is a common question, and the honest answer depends on what you’re trying to accomplish.

When DIY Can Work

Some crawl space improvements are within reach of handy homeowners:

Vapor Barrier Installation: Laying a ground vapor barrier is labor-intensive but doesn’t require specialized skills. If your crawl space has adequate height (3+ feet) and you’re comfortable working in tight spaces, this is DIY-able.

Rigid Foam Board on Walls: Cutting and installing foam board panels on flat, accessible foundation walls can be a weekend project. You’ll need construction adhesive, mechanical fasteners, and patience.

Sealing Small Gaps: Caulking and foam-filling minor air leaks around pipes, wires, and penetrations is straightforward DIY work.

DIY Requirements:

- 3+ feet of clearance to work safely

- No existing moisture or mold problems

- Basic construction skills and tools

- Physical ability to work in confined spaces

- Time commitment (expect multiple weekends)

When to Hire Professionals

Professional installation is essential for:

Spray Foam Insulation: This is not a DIY material. It requires:

- Specialized equipment costing thousands of dollars

- Training in proper mixing ratios and application techniques

- Safety gear and protocols (occupants must vacate during installation)

- Knowledge of building codes and fire safety requirements

Existing Moisture or Mold: If your crawl space has water intrusion, mold growth, or high humidity, you need professional assessment and remediation before any insulation work.

Comprehensive Encapsulation: Full encapsulation systems integrate multiple components (drainage, barriers, insulation, dehumidification) that require experience to install correctly.

Difficult Access: Low clearance, irregular shapes, or obstacles make professional installation more efficient and safer.

Warranty Considerations: Professional installation typically includes warranties on both materials and workmanship. DIY work has no such protection.

Cost-Benefit Analysis

| Factor | DIY | Professional |

|---|---|---|

| Material Cost | Same | Same |

| Labor Cost | $0 (your time) | $500-$1,500 |

| Time Investment | 20-40 hours | None |

| Quality Assurance | Self-inspection | Professional guarantee |

| Warranty | Material only | Materials + workmanship |

| Risk of Mistakes | Higher | Lower |

| Best For | Simple projects | Complex/comprehensive work |

André Desjarlais, Program Manager at Oak Ridge National Laboratory, offers this advice: “Forget the product; pick the best contractor.” For spray foam and comprehensive projects, professional installation isn’t just recommended—it’s essential.

Crawl Space Insulation in Alaska: Desert Climate Considerations

Alaska’s unique climate presents both challenges and opportunities for crawl space insulation.

Anchorage Climate Challenges

Extreme Summer Heat: Anchorage regularly exceeds 115°F in summer. Uninsulated crawl spaces can reach temperatures that stress HVAC systems and bake ductwork.

Monsoon Moisture: Alaska’s monsoon season (July-September) brings sudden, intense rainfall and humidity spikes. Water intrusion and elevated humidity can cause problems in unprepared crawl spaces.

Dramatic Temperature Swings: Day-to-night temperature differences of 30°F or more are common, especially in spring and fall. This thermal cycling stresses building materials and contributes to comfort problems.

Dust Infiltration: Alaska’s famous dust storms (haboobs) drive fine particles into every unsealed opening. Crawl spaces with open vents become dust collection zones.

Minimal Freezing Risk: Unlike cold-climate states, Alaska rarely experiences prolonged freezing temperatures. This means less concern about frozen pipes but also means some homeowners underestimate the value of insulation.

Best Insulation Approaches for Alaska

Given Alaska’s climate (Zone 7-8, among the coldest in the U.S.), here’s what works best:

Closed-Cell Spray Foam: The premier choice for Alaska crawl spaces. It provides:

- Excellent moisture resistance during monsoon season

- High R-value in minimal thickness

- Complete air sealing against dust and pests

- Durability in temperature extremes

Target R-Value: R-13 to R-19 for optimal performance in Alaska’s climate

Sealed Crawl Space Approach: Even in Alaska’s dry climate, sealed and conditioned crawl spaces outperform vented designs. Research shows up to 20% energy savings in Anchorage’s extreme heat.

Monsoon Preparation: Ensure vapor barriers are installed and sealed before monsoon season. Address any drainage issues around foundations.

Alaska-Specific Rebates and Incentives

Alaska homeowners have access to generous insulation incentives:

EFFICIENCY ARIZONA (Alaska Governor’s Office)

- HOMES program: Up to $4,000 (or $8,000 for lower-income households)

- HEAR program: Up to $14,000 for qualifying households

APS (Alaska Public Service): $250 rebate through Home Performance Program

SRP (Salt River Project): Up to $600 for attic insulation, $250 for air sealing

Federal Tax Credit: 30% of materials, up to $1,200 annually

Combined Savings: Anchorage homeowners can potentially access $2,700 to $4,500+ in rebates and tax credits on a comprehensive insulation project.

Crawl Space Insulation Problems: What to Watch For

Even well-intentioned insulation projects can encounter problems. Here’s what to watch for—and how to prevent issues.

Moisture and Mold Issues

Moisture is the enemy of crawl space insulation. Warning signs include:

- Musty odorsrising from below your floors

- Visible mold or mildewon wood framing or insulation

- Condensationon pipes, ducts, or foundation walls

- Standing wateror damp soil in the crawl space

- High humidity readings(above 60% relative humidity)

Prevention:

- Install vapor barrier before or with insulation

- Ensure proper drainage around foundation (gutters, grading, downspouts)

- Use moisture-resistant insulation materials (spray foam or rigid foam)

- Add dehumidification for humidity control

- Fix any water intrusion before insulating

If mold is present: Do not install new insulation over mold. Professional remediation is required first.

Sagging or Falling Insulation

This is the classic failure mode of fiberglass batts in crawl spaces:

Signs of failure:

- Insulation hanging below floor joists

- Gaps where insulation has fallen completely

- Compressed or discolored insulation

- Increased energy bills or cold floors

Why it happens: Gravity plus moisture. Fiberglass absorbs humidity, becomes heavy, and loses its grip between joists. This process accelerates in vented crawl spaces.

Solution: Remove failed fiberglass and upgrade to spray foam or rigid foam wall insulation. This addresses the root cause rather than repeating the same mistake.

Pest Infestations

Crawl spaces attract rodents, insects, and other unwanted guests. Warning signs:

- Droppings or nesting materials

- Damaged or displaced insulation

- Gnaw marks on wood or wiring

- Unusual sounds from below floors

Prevention: Sealed, conditioned crawl spaces are far less attractive to pests than vented, damp ones. Spray foam insulation is pest-resistant and eliminates entry points. Professional pest inspection before encapsulation is recommended.

Get a Professional Assessment

Before investing in crawl space insulation, consider getting athermal inspectionto identify existing problems and prioritize improvements. This can save money by targeting the most impactful areas first.

FAQ Section

Frequently Asked Questions

How much does crawl space insulation cost?

Crawl space insulation costs $1.00 to $4.50 per square foot, depending on material and complexity. For a typical 1,000 square foot crawl space, expect to pay $2,600 to $5,000 for professional installation. Spray foam costs $2-$5 per square foot; rigid foam costs $1-$4 per square foot. Factor in potential removal of old insulation ($0.75-$2/sq ft) if needed. Federal tax credits and Alaska rebates can reduce costs by $2,700-$4,500.

Will insulating my crawl space stop cold floors?

Yes—when done correctly. The key is insulating crawl space walls, not the ceiling. Wall insulation creates a conditioned space that stays closer to indoor temperature, eliminating the thermal bridge causing cold floors. You must also seal foundation vents and air leaks. Fiberglass batts between joists typically fail to solve cold floor problems because they sag, allow air infiltration, and don’t address the underlying issue.

What is the best insulation for a crawl space?

Closed-cell spray foam is the best insulation for crawl spaces. It offers the highest R-value per inch (R-6 to R-7), resists moisture completely, provides air sealing, and lasts 20+ years. Rigid foam board is a good alternative at lower cost, offering R-4 to R-6.5 per inch and DIY-friendly installation. Avoid fiberglass batts in crawl spaces—they absorb moisture, sag, promote mold, and consistently fail within 5-15 years.

Should I insulate my crawl space ceiling or walls?

Insulate the walls, not the ceiling. Building Science Corporation research proves that sealed crawl spaces with wall insulation outperform vented crawl spaces with ceiling insulation in energy efficiency, moisture control, and durability. Wall insulation creates a conditioned space that protects pipes and ducts while eliminating thermal bridging through floor joists. The International Residential Code endorses this approach.

What is crawl space encapsulation vs insulation?

Insulation controls temperature (thermal barrier), while encapsulation controls moisture (vapor barrier + sealed space). Insulation stops cold floors; encapsulation prevents mold and moisture damage. Most homes benefit from both—comprehensive encapsulation with wall insulation provides optimal results. Insulation alone won’t solve moisture problems, and encapsulation alone won’t stop cold floors.

Does crawl space insulation save money on energy bills?

Yes—significantly. Properly insulated crawl spaces reduce heating and cooling costs by 15-30%, according to DOE and EPA research. For a typical Alaska home spending $2,000-$3,000 annually on energy, that’s $300-$900 in savings per year. Most projects pay for themselves within 3-7 years through energy savings alone, not counting improved comfort and home value.

How long does crawl space insulation last?

Spray foam insulation lasts 20+ years—often the lifetime of the home—when properly installed. Rigid foam board lasts 20-40 years. Fiberglass batts in crawl spaces typically fail within 5-15 years due to moisture absorption and sagging. Longevity depends on moisture control: insulation combined with proper vapor barriers and humidity control lasts far longer than insulation alone.

Can I DIY crawl space insulation or should I hire a professional?

DIY works for vapor barrier installation and rigid foam board on accessible walls if you have construction skills, adequate clearance (3+ feet), and no moisture problems. Spray foam requires professional installation—specialized equipment, safety protocols, and expertise are essential. For comprehensive encapsulation or any crawl space with existing moisture or mold issues, professional installation is strongly recommended.

What R-value do I need for crawl space insulation?

R-value requirements depend on climate zone. For Alaska (Zone 7-8), code minimum is R-20+ for crawl space walls and R-38 for floors—among the highest requirements in the nation. Optimal performance in Anchorage often exceeds code minimums, with many homeowners choosing R-25 to R-30 for walls. Check local building codes for specific requirements, as some municipalities require even higher values.

Do I need a vapor barrier with crawl space insulation?

Yes—in almost all cases. A vapor barrier (6-20 mil polyethylene) prevents ground moisture from rising into your crawl space, where it can damage insulation and promote mold. The International Residential Code requires vapor barriers in unvented crawl spaces. Thicker barriers (10-20 mil) last longer and resist punctures. The barrier should cover the entire floor, overlap seams 6-12 inches, and extend up foundation walls.

Should I remove old insulation before installing new?

Remove old insulation if it’s wet, moldy, pest-infested, sagging, or falling. Spray foam requires clean surfaces, so old ceiling insulation must be removed. If existing insulation is dry and in good condition, and you’re adding wall insulation to a previously vented crawl space, the old ceiling insulation can sometimes remain. When in doubt,removalis often worth the extra cost for a fresh start.

How do I prevent mold in my insulated crawl space?

Prevent mold by controlling moisture: install a heavy-duty vapor barrier on the ground, use moisture-resistant insulation (spray foam or rigid foam), seal all vents and air leaks, maintain humidity below 60% with a dehumidifier, and fix any water intrusion sources (gutters, grading, foundation cracks). Avoid fiberglass batts, which trap moisture. Regular inspections help catch problems early.

Conclusion Section

Stop Cold Floors Today: Your Next Steps

Cold floors are not inevitable—they’re a symptom of a problem with a proven solution. Modern building science has shown us that sealed, conditioned crawl spaces with spray foam wall insulation dramatically outperform the outdated vented crawl spaces of the past.

The key takeaways:

- Insulate walls, not ceilings: This is the single most important change in crawl space insulation practice. Wall insulation creates a conditioned space that eliminates cold floors at the source.

- Choose moisture-resistant materials: Closed-cell spray foam is the gold standard. Rigid foam board is a solid alternative. Avoid fiberglass batts in crawl spaces.

- Combine insulation with encapsulation: Address both temperature and moisture for optimal results. A comprehensive approach delivers 15-30% energy savings.

- Take advantage of incentives: Federal tax credits of up to $1,200 and Alaska rebates of $2,700-$4,500 make 2025 an ideal time to invest in crawl space insulation.

- Invest in professional installation: For spray foam and comprehensive projects, professional installation ensures quality, warranty protection, and long-term performance.

Ready to eliminate cold floors for good?

Foamology Insulation serves Anchorage and the surrounding Alaska communities with professional crawl space insulation and encapsulation services. Our experienced team uses premium spray foam materials and proven techniques to deliver results that last.

Contact Foamology today for a free crawl space inspection and quote. Stop walking on cold floors—and start saving money on energy bills.

Author/Source Attribution

This article was researched and written to provide comprehensive, accurate information about crawl space insulation. Sources include the U.S. Department of Energy, Environmental Protection Agency, Building Science Corporation, Oak Ridge National Laboratory, and other authoritative industry resources.

About the Author: Foamology Insulation Team

Professional insulation contractors serving Anchorage, Alaska with expertise in spray foam insulation, crawl space encapsulation, and energy-efficient building solutions.